Where does vanilla extract come from?

It’s in the name – it’s made by soaking aged/cured vanilla beans in ethanol and water to ‘extract’ all of their flavour compounds. Read on more as we show you just exactly how it is done, the benefits and where you can use Plant-Ex’s vanilla extract in application…

Step 1:

First things first, we bring sustainably sourced vanilla beans from Madagascar. Vanilla pods come from the pods of the Orchid Plant, Vanilla Planifolia delivering the most intense flavour and aroma.

Step 2:

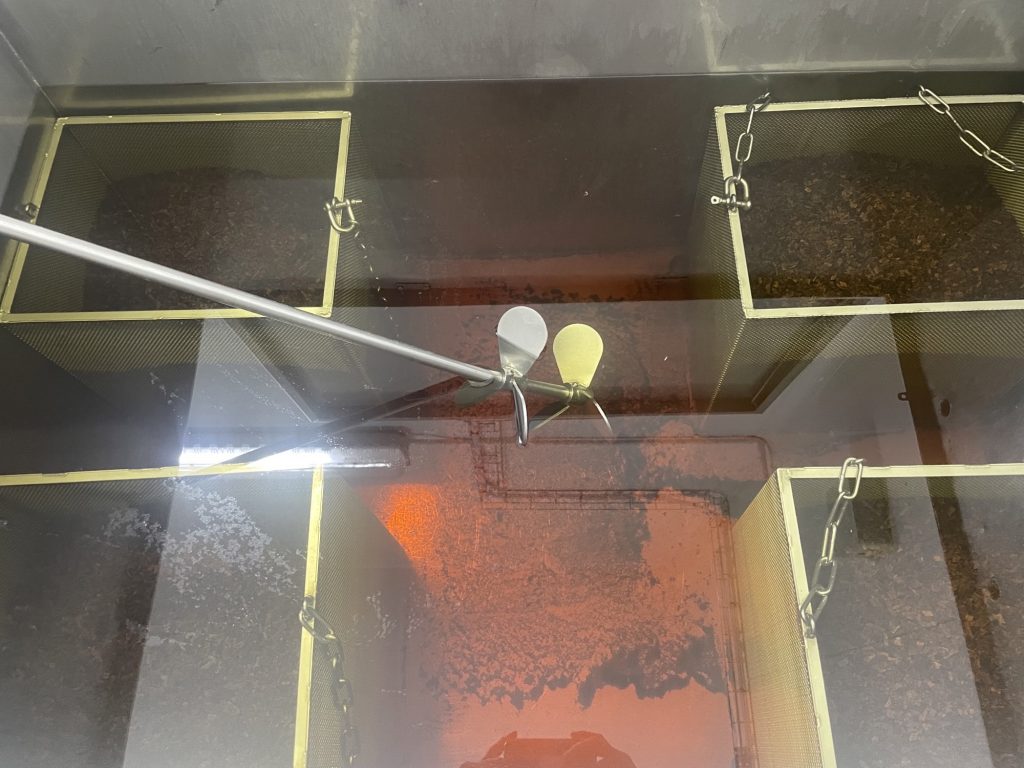

At Plant-Ex we have an extraction tank with the sole purpose to extract vanilla. This is where the bulk of the process is completed.

To begin the process, a quantity of the vanilla pods are equally distributed into separate cages in the extraction tank, as seen below in order to keep them loose and open to the extraction liquid. Pumping and circulating the liquid around the beans for an extended period of time allows a complete extraction.

Step 3:

Now the vanilla pods are in the tank… we need to sterilise them. This is done by adding ethanol into the extraction tank which is then gently mixed around with an air mixer. The cages have holes in the bottom and sides so the ethanol can move through, being able to extract the flavour compounds from the vanilla pods.

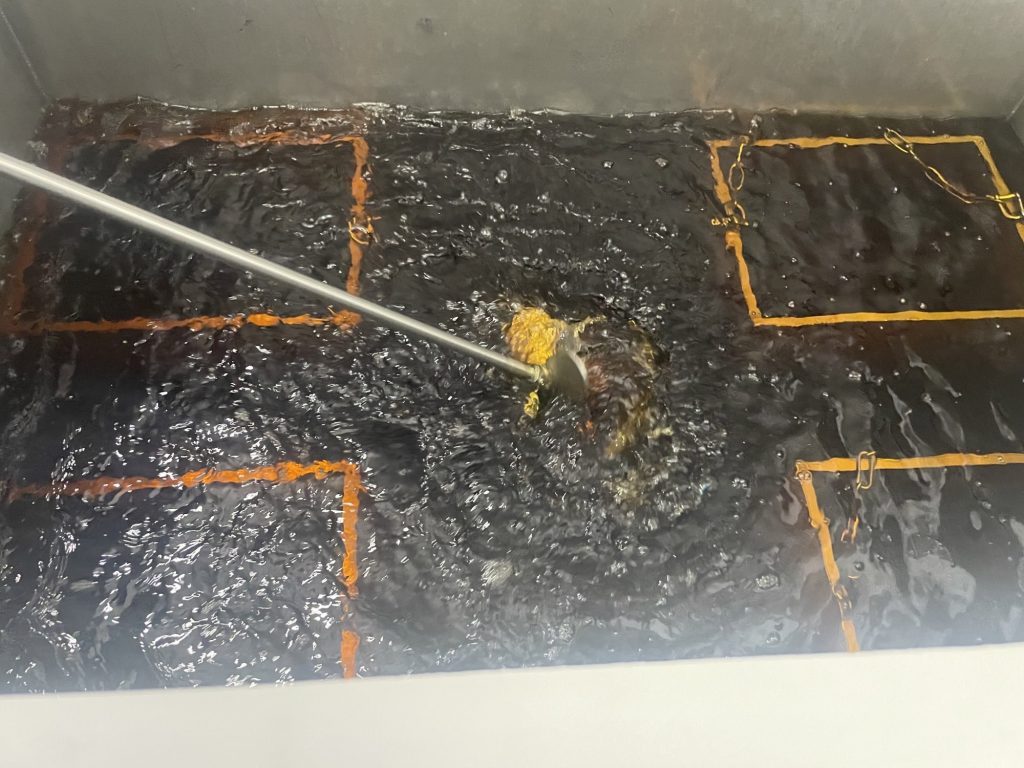

The air mixer allows the extraction to take place without disturbing the pods as it gently agitates the pods to extract the flavour compounds. This is done for a minimum of 24 hours (the longer the beans are held in an alcohol solution, the better the final extraction of oil/fat soluble compounds in the final extract). The solution starts as a relatively clear liquid and gradually develops into a rich aromatic soup comprising all of the true notes of Vanilla Beans.

Step 4:

Following the ethanol process, we add water to the extraction tank which helps to pull aqueous compounds from the beans which further adds to the full rounded profile of the finished extract. A period of time allows the strength of the extract to develop and mature – whereupon the first stages of testing will occur.

Step 5:

Quality Control will ensure is compliant with our internal standards and passes all the necessary tests. E.g. it is tested for brix content (which is the solid content compared to liquid content). If the solid content isn’t high enough we will run the extraction tank for longer, extracting more of the flavour compounds from the vanilla pods. Most importantly, the team will conduct triangle taste testing versus a known standard to assure that our profile and strength are meeting the expectations of our clients.

We have parameters the sample must reach before we can pump the extract out, to ensure every batch is made to the same high standard.

Step 6:

Once the sample meets the required standards, the extract is then pumped out of the extraction tank through fine mesh filters. This is important because as the vanilla is extracted the beans can slowly break down and potentially allow seeds etc to flow into the liquid, so the filter ensures no solids can transfer into our finished products. Additionally – the seeds which are captured in the filters are dried and sold for speckled effect in Bakery and Ice Cream applications.

Step 8:

This vanilla extract is then further processed into a variety of different strength vanilla extracts ready to be sold by the Plant-Ex Commerical Team!

What are the benefits of using Plant-Ex’s Vanilla Extracts?

- By using Plant-Ex’s Vanilla Extract, you can claim ‘Madagascan’ provenance on your packaging. This will help to entice consumers as it provides a story behind the product and therefore they are more comfortable with the authenticity of the item.

- The extract is derived from actual vanilla pods, so it is therefore depictable on the packaging, meaning you can put an image of vanilla pods on the back of pack.

- Using extracts provides a more intense flavour at a smaller dosage, which is more cost-effective.

Vanilla is a go-to flavour that has hundreds of different profiles – check out our blog post here, where we break down the different flavour profiles of vanilla to help you understand what profile would be best suited to your application.

Where can you use Plant-Ex’s Vanilla Extracts?

Vanilla Extract is extremely versatile and can be used in all sorts of applications from bakery to sports nutrition. It can be used in custard slices, sponge cakes, delicious milkshake or even a protein bar.

If you require any additional information or want to try a sample don’t hesitate to get in touch at sales@plant-ex.com