Plant-Ex are here to meet all your needs…

Colour matching is a popular service that is offered to our new and existing customers at Plant-Ex. It is the process whereby we match the colour supplied by your incumbent supplier in order to offer a more competitive price, shorter lead times and a better level of service – all while maintaining the same shade in your application!

If you are interested in the process of how we match a colour, carry on reading as this blog takes you through each individual step, using the example of an orange colour.

Step 1:

Initially, a customer gets in touch with Plant-Ex in order to raise a matching brief. We require the customer to send a small sample, a copy of the product specification, a target price, an indication of annual volumes and what the product is being used in.

The application is important to us, as some colours can be sensitive to heat, pH or light.

Using the information supplied by the customer, an internal brief is raised which gets allocated to one of our Colour Specialists.

Step 2:

The Colour Specialist then assesses the product specification to determine whether we already have a current match within our product portfolio. If not, a new product needs to be developed.

Read on to find out how this is done…

Step 3:

Using the sample supplied by the customer, we weigh roughly 0.1% of the colour into a beaker to create a water solution. We call this the ‘standard’, which gets loaded onto our X-rite and is referred back to during the matching trials.

Step 4:

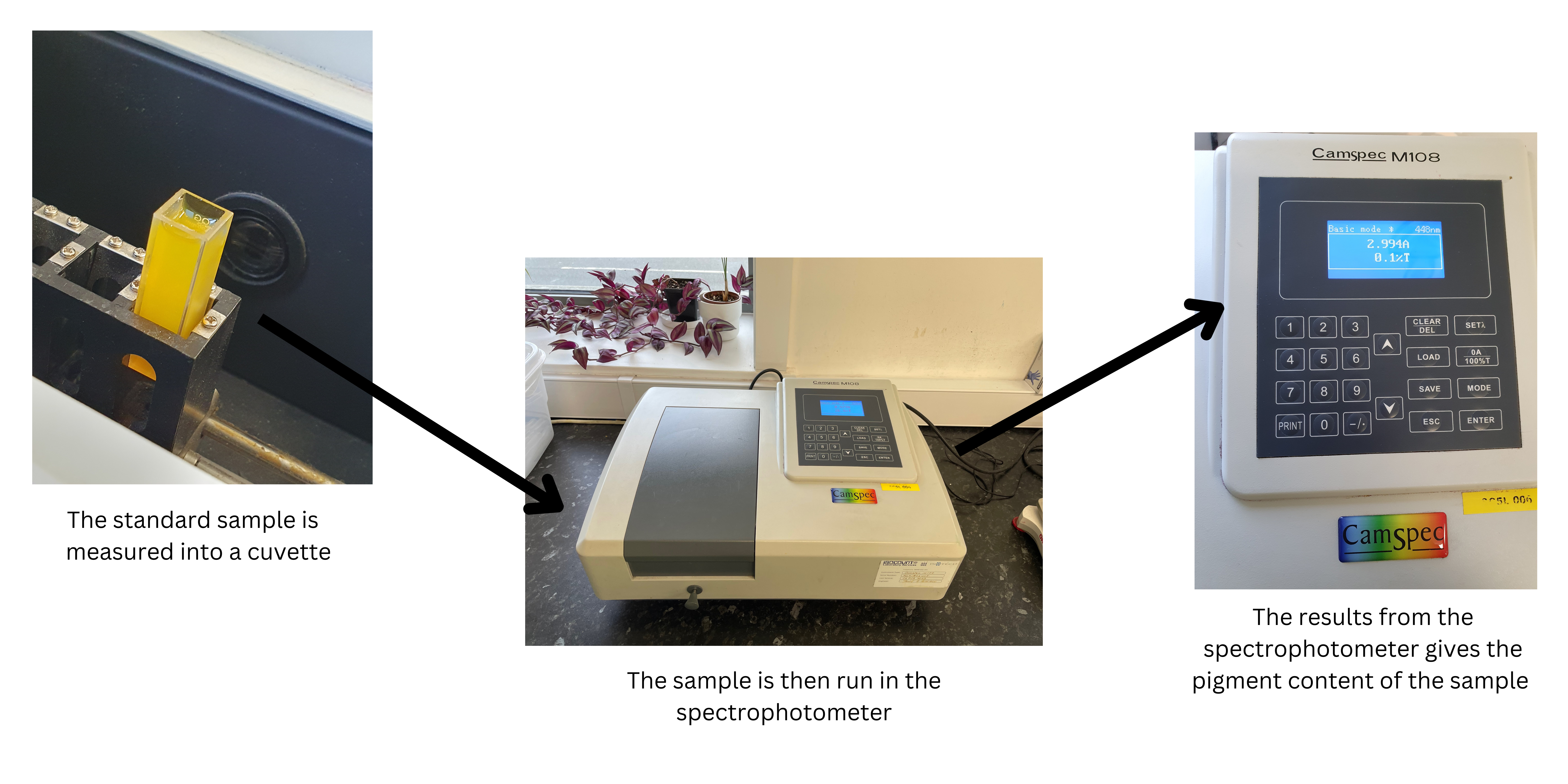

The sample is then input into our spectrophotometer, allowing us to analyse the pigment content. This is done by using the water solution made in step 3, and putting it into a cuvette which is then put into the spectrophotometer.

A beam of light is then passed through the sample and each compound in the solution absorbs or transmits light over a certain wavelength. This will provide a reading of the pigment percentage, telling you the amount of pigment compared to the solid.

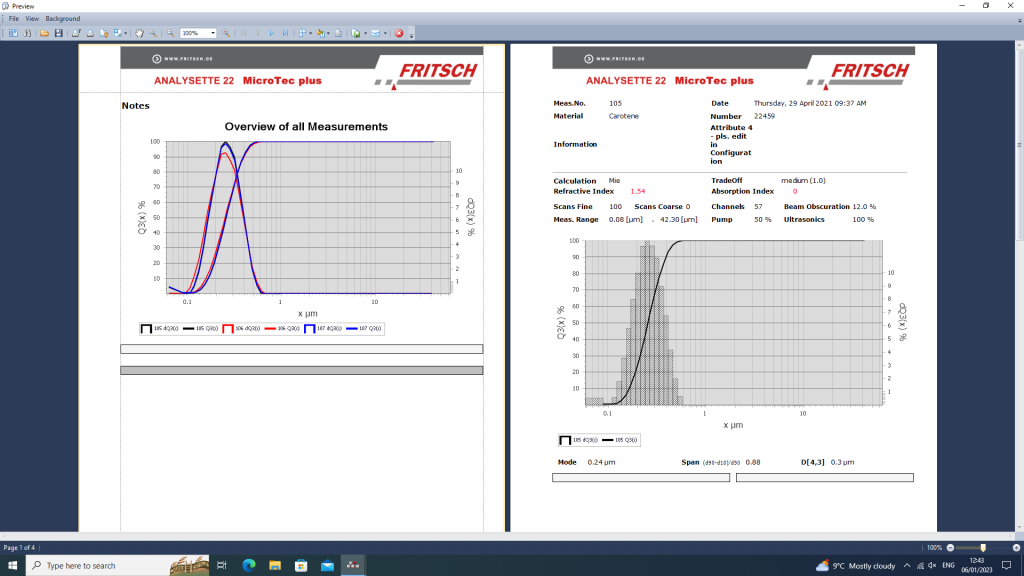

*It is important to note that if the colour we are matching is an emulsion, we would also run it under our laser particle size analyser. This is because particle size is extremely important for emulsions, as it will affect the stability of the sample, as well as brightness.

When using our Particle Size Analyser, a laser is shone through the sample and analyses the particles; the data is then fed back to the machine and the particle size is calculated. A graph is produced like the below (this way we can ensure the particle size of our match is the same as the customers standard).

Step 5:

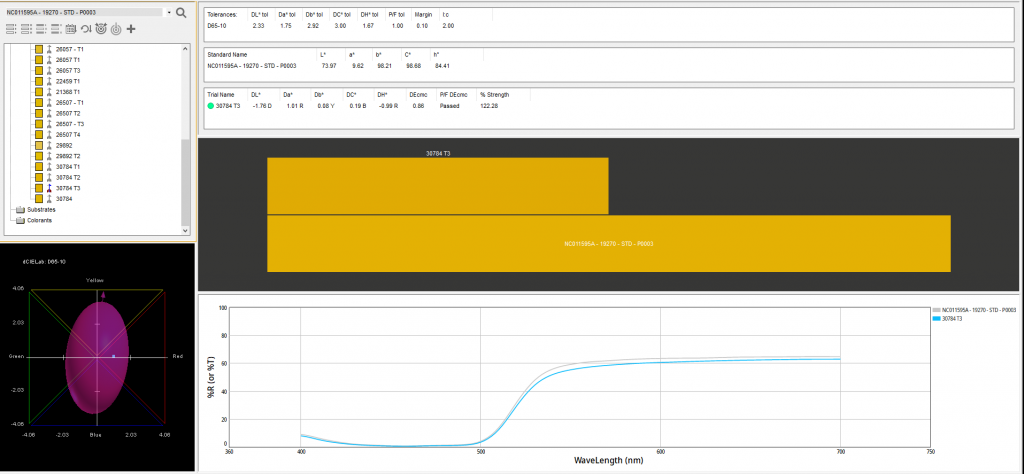

The standard is then set on the system into the colorimetry software database (X-Rite).

This produces a report like the below. This then allows us to compare all the trial samples that are made against the standard – therefore allowing us to get an exact match.

Below is an example of NC011595A Natural Beta Carotene Emulsion run on the X-rite, showing you an idea of the colour.

After these tests have been run, we have got the basis of what to work on for the match. This is because we have all the relevant information from the product spec, pigment content, particle size and an idea of the colour. All the parameters need to be the same as the customer’s standard in order to give a product match, leaving no room for error.

Step 6:

A trial sample is made based on all the relevant parameters, which initially gets run on the spectrophotometer to obtain a colour pigment percentage. This is then compared against the standard sample that was loaded onto the X-rite, to ensure the target sample holds the same pigment percentage.

Step 7:

Once the pigment percentage is correct, the sample will then be run through various pieces of equipment to ensure it is an exact match against the customer’s standard;

- using the X-Rite we want to ensure the colour is an exact match. We do this by analysing the colour and ensuring D.ECMC <2, which is undetectable to the human eye

- the sample is also run against the particle size analyser if needed, to ensure the particles are the same size

This can take up to a few trials until it matches the standard. How long it takes is dependent on the product, as some colours are easier than others!

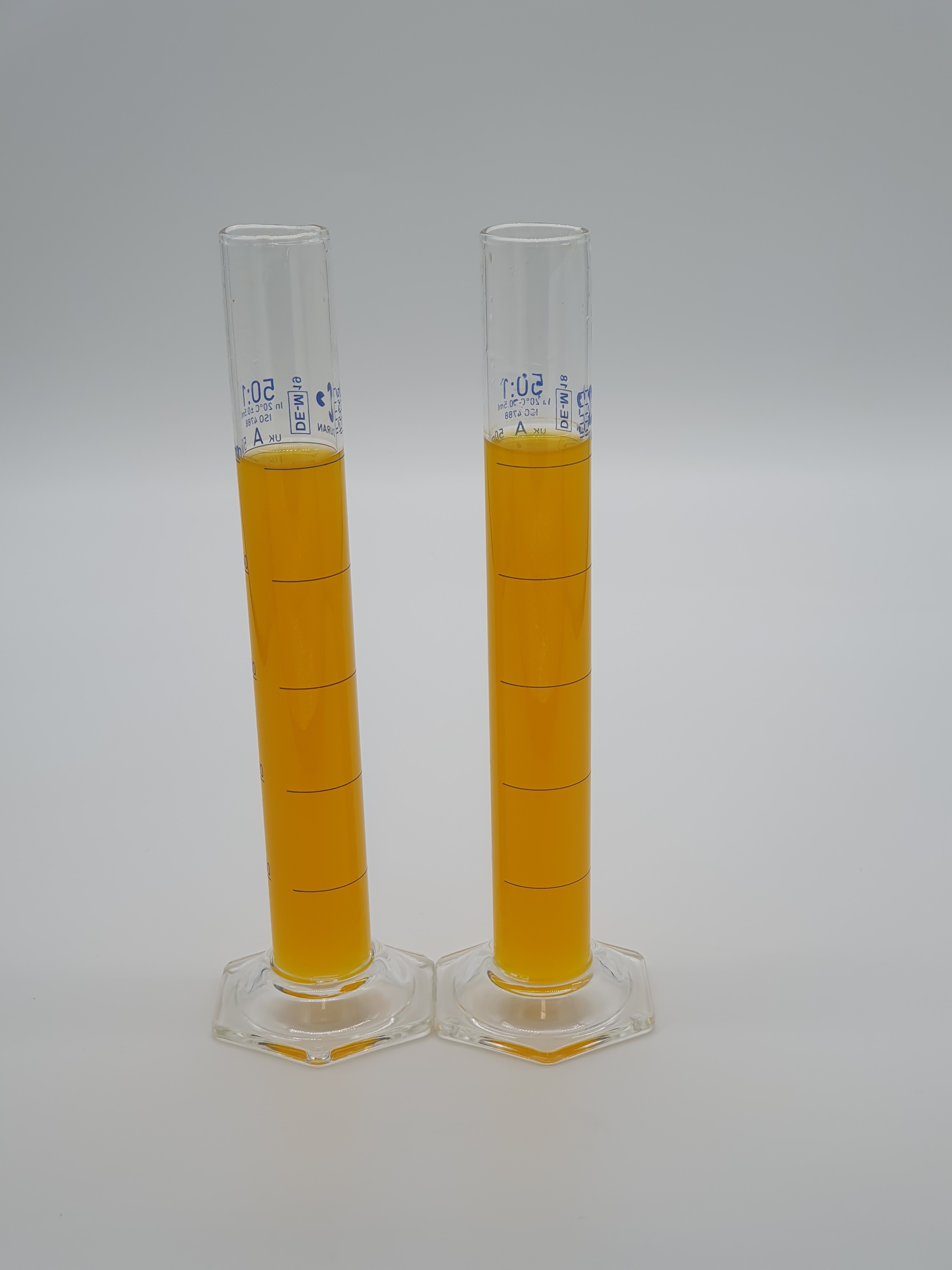

Here is an example of a match the Colour Specialists made against a beta carotene – it passed with flying colours!

Step 8:

Once the target sample has passed all the tests and an exact match has been created, a new product code is generated on our internal system and a formulation is loaded onto the system. Alongside this, a specification and MSDS are generated.

All the testing information and newly generated product code is inputted into the brief, along with any feedback. The relevant Sales person passes this information onto the customer, and sends a sample, spec and quote for customer approval.

As you can see there is an extremely scientific process behind colour matching. Not only can we match your colours, but we can also match your flavours. Check out our flavour matching blog post here to see how this is done: The Process of Matching A Flavour.

Our technical team are more than happy to help with any questions you may have and are willing to help, so please get in touch at sales@plant-ex.com.